The doorbell rings... Who could it be? It's 6:30 pm, and almost time for me to get ready for bed. Who would call on me at this hour?

I walked to the door (which is mostly glass) and outside I see a smiling Gracie, holding a plate with homemade cookies. I didn't spot it until she'd left, but under the cookies was an envelope with a card in it. The cookies and the card are in the photo at right (click to embiggen). Well, to be precise, the cookies were in the photo. Now they're in my stomach, along with a giant glass of milk.

Gracie hopes that I like sugar cookies with lots of orange cream cheese frosting. Why, yes, Gracie. Yes I do :)

Tuesday, September 23, 2014

Barn: second story shaping up...

Barn: second story shaping up... The builders have been busy today! Nearly all the joists are in place, the framing for the stairway and the hatch are finished except for two joists (they ran out of metal hangers), and all but a few square feet of the floor are in place (they ran out of wafer board!). Tomorrow morning they'll finish those last details up, when the new load of lumber arrives, and then the second story walls start going up.

In the last photo below, you can see one of the builders wielding a nail gun. After watching these guys working for the past few weeks, I think this may be the single most useful tool they have. It's an air powered gun that holds a magazine of 250 nails. But the best part is how it's triggered. One mode uses a conventional trigger, just like on an actual gun. The other mode uses pressure on the very tip – you put the nose of the gun where you want the nail and then just press gently. A skilled user can put a nail ever 8" down the 4' length of a joist running under the floor boards in less than two seconds. That works out to 3.5 nails per second, each one perfect straight and perfectly driven. A skilled framer wielding a hammer might be able to do one nail every two seconds, but won't be able to sustain that for very long. They used the same nail gun to tack all the studs in place, making very short work of that more challenging nailing job (challenging because you're nailing at close to a 45° angle)...

In the last photo below, you can see one of the builders wielding a nail gun. After watching these guys working for the past few weeks, I think this may be the single most useful tool they have. It's an air powered gun that holds a magazine of 250 nails. But the best part is how it's triggered. One mode uses a conventional trigger, just like on an actual gun. The other mode uses pressure on the very tip – you put the nose of the gun where you want the nail and then just press gently. A skilled user can put a nail ever 8" down the 4' length of a joist running under the floor boards in less than two seconds. That works out to 3.5 nails per second, each one perfect straight and perfectly driven. A skilled framer wielding a hammer might be able to do one nail every two seconds, but won't be able to sustain that for very long. They used the same nail gun to tack all the studs in place, making very short work of that more challenging nailing job (challenging because you're nailing at close to a 45° angle)...

Rope swing optimization...

Rope swing optimization... Let's say you had a rope swing, and you wanted to use it to go as far as possible horizontally. How would you do it? Here's more than you ever wanted to know about the subject...

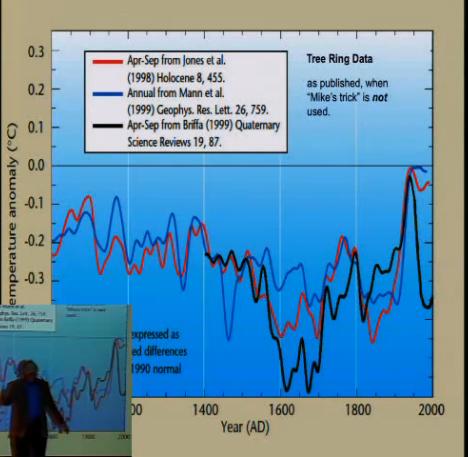

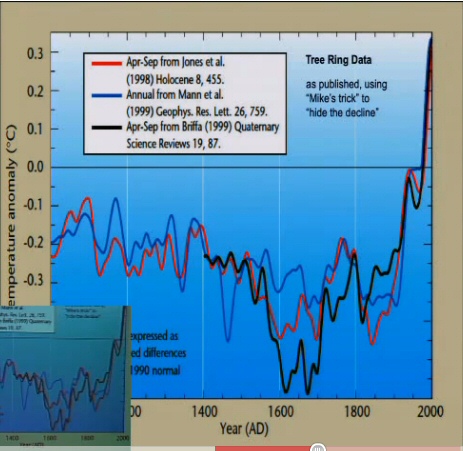

Mann's “Hide the Decline” ruthlessly exposed...

Mann's “Hide the Decline” ruthlessly exposed... Jean S., posting at Climate Audit, has posted a carefully researched chronology of events that exposes “Mike’s trick” as the deliberate fraud we all knew it was. The only credible conclusion you can come to after reading Jean's awesome piece is that Mann was most definitely involved in the deliberate misleading of the IPCC, his fellow scientists, and the public at large. His “trick” created the memorable “hockey stick” graph from the thinnest of air. Below are two versions of the famous graph (click to embiggen): on the left without “Mike’s trick”; on the right with it...

Mike Mann, schlub scientist...

Mike Mann, schlub scientist...

Paving: it's time for “road base”...

Paving: it's time for “road base”... The paving guys are now doing the last step before the actual asphalt goes on: they're laying down a 3" thick layer of “road base” – a mixture of fine gravel and very fine (almost powdery) dirt. This will be wet down and carefully smoothed to form a layer upon which the asphalt will be put down. They'll be done with this today, but the asphalt won't go on until the paving machine is available – and I'm not sure when that is.

The first two photos below show where the ends of a 3" diameter “sleeve” are; this is partly as documentation for myself. The idea of the sleeve is to provide a way to run pipes or wires under the pavement, without having to resort to expensive horizontal drilling. This sleeve is 30' long, and runs diagonally under the pavement just 10' or so from our house. Next year I hope to put a greenhouse up just west of the pavement, and when I do, I'll use this sleeve to run water and gas (and maybe electricity) out to it from the house...

The first two photos below show where the ends of a 3" diameter “sleeve” are; this is partly as documentation for myself. The idea of the sleeve is to provide a way to run pipes or wires under the pavement, without having to resort to expensive horizontal drilling. This sleeve is 30' long, and runs diagonally under the pavement just 10' or so from our house. Next year I hope to put a greenhouse up just west of the pavement, and when I do, I'll use this sleeve to run water and gas (and maybe electricity) out to it from the house...

Barn: the second floor progresses...

Barn: the second floor progresses... Yesterday the builders put up the last of the glulam beams (that's one being sawed in the middle photo below), and started laying the second floor joists on top of them. Today they've finished with the joists, including framing out a place for the stairs to go, and a place for a giant hatch (10' by 4') through which I can lift big objects with a block and tackle. They've also started putting down the flooring.

Things are moving along quickly on the barn!

Things are moving along quickly on the barn!

The great water adventure...

The great water adventure... Last night as I was just getting ready to head for bed, my phone rang. It was my neighbor, Tim D., calling to let me know that we had a “water problem” – our neighbor's teen daughter (Gracie L.) was mowing their yard, and accidentally struck and broke one of the irrigation water “risers”. That's precisely the same thing I had done earlier this year, so I knew exactly what it was like for Gracie :)

Tim and I talked for a couple minutes, and figured out that between the two of us we had almost everything needed to repair that broken riser, both parts and tools. We'd need one more part, but Tim figured we could find a neighbor who had that one. So Tim and I gathered up what we'd need, and met over where the broken riser was gushing water 20' or so high.

As I walked up, another neighbor got the water shut off. The geyser was gone, but a small pond remained around the broken riser. People were gathering – adults and kids from the immediately adjacent neighbors. Shovels and buckets appeared, and an organized effort to drain the water around the riser got started (this was necessary because the solvent used to weld PVC pipes together only works on dry pipes). The drainage effort was made more difficult by the fact that the broken riser was near the low point of a few hundred yards of pipe, and all of that was now draining backwards through the broken riser.

Now this probably doesn't sound like a whole lot of fun, but ... we were actually all having rather a grand time. There was much joshing and laughter. Two dogs (Annie and Dallas) were splashing around in the water, spewing mud in every direction, splattering us all from head to foot – and we all were laughing about it.

Eventually the draining was finished, and we got the water level down. We used a towel to dry the pipe, then cut and glued the new parts in place. A neighbor did have the missing part. It was after dark by the time we finished, but I had brought a nice LED flashlight that was providing plenty of light.

When I got home, I discovered a sad email from Gracie, the girl who had accidentally broken the riser. She wanted to tell me just how very sorry she was for breaking my riser. My riser?!? Until the moment I read that email, it had never occurred to me that the broken riser was mine – but Gracie was right about that: it was on our property. She was mowing a little piece of what I think of as their lawn when she broke the riser, but that 6' or so wide piece of lawn is actually on our property. The whole time we were all working on that thing, I was thinking that we were all helping Gracie and her family out – but in reality that whole crew was helping me out. What an odd feeling that was as I changed mental gears there!

I love living up here...

Tim and I talked for a couple minutes, and figured out that between the two of us we had almost everything needed to repair that broken riser, both parts and tools. We'd need one more part, but Tim figured we could find a neighbor who had that one. So Tim and I gathered up what we'd need, and met over where the broken riser was gushing water 20' or so high.

As I walked up, another neighbor got the water shut off. The geyser was gone, but a small pond remained around the broken riser. People were gathering – adults and kids from the immediately adjacent neighbors. Shovels and buckets appeared, and an organized effort to drain the water around the riser got started (this was necessary because the solvent used to weld PVC pipes together only works on dry pipes). The drainage effort was made more difficult by the fact that the broken riser was near the low point of a few hundred yards of pipe, and all of that was now draining backwards through the broken riser.

Now this probably doesn't sound like a whole lot of fun, but ... we were actually all having rather a grand time. There was much joshing and laughter. Two dogs (Annie and Dallas) were splashing around in the water, spewing mud in every direction, splattering us all from head to foot – and we all were laughing about it.

Eventually the draining was finished, and we got the water level down. We used a towel to dry the pipe, then cut and glued the new parts in place. A neighbor did have the missing part. It was after dark by the time we finished, but I had brought a nice LED flashlight that was providing plenty of light.

When I got home, I discovered a sad email from Gracie, the girl who had accidentally broken the riser. She wanted to tell me just how very sorry she was for breaking my riser. My riser?!? Until the moment I read that email, it had never occurred to me that the broken riser was mine – but Gracie was right about that: it was on our property. She was mowing a little piece of what I think of as their lawn when she broke the riser, but that 6' or so wide piece of lawn is actually on our property. The whole time we were all working on that thing, I was thinking that we were all helping Gracie and her family out – but in reality that whole crew was helping me out. What an odd feeling that was as I changed mental gears there!

I love living up here...

Mantle: it's finished!

Mantle: it's finished! Yesterday I got the mantle, with its two corbels, mounted to the living room wall over where the fireplace will be. I'm very pleased with the result of my mounting plate design – the finished mantle is very strong, doesn't jiggle at all, and the reclaimed wood will all be exposed once the rock is in. The plywood mounting plates that are visible now will be completely covered by mortar and rock. Behold (and use your imagination for the rock)!

Subscribe to:

Comments (Atom)